Solving Drying Challenges in the Chemical Industry: Why Choose Explosion-Proof Vacuum Drying Equipment?

24 08,2025

Zhengzhou Keda Machinery Equipment Co., Ltd.

Solution

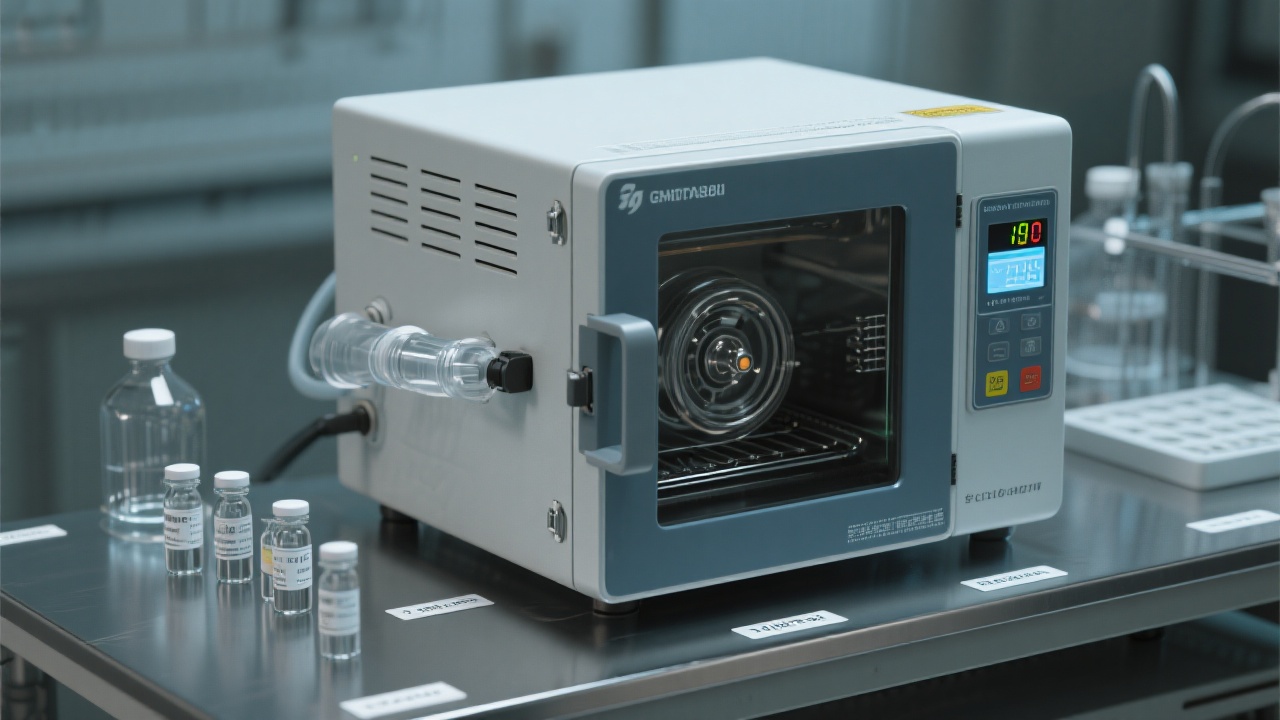

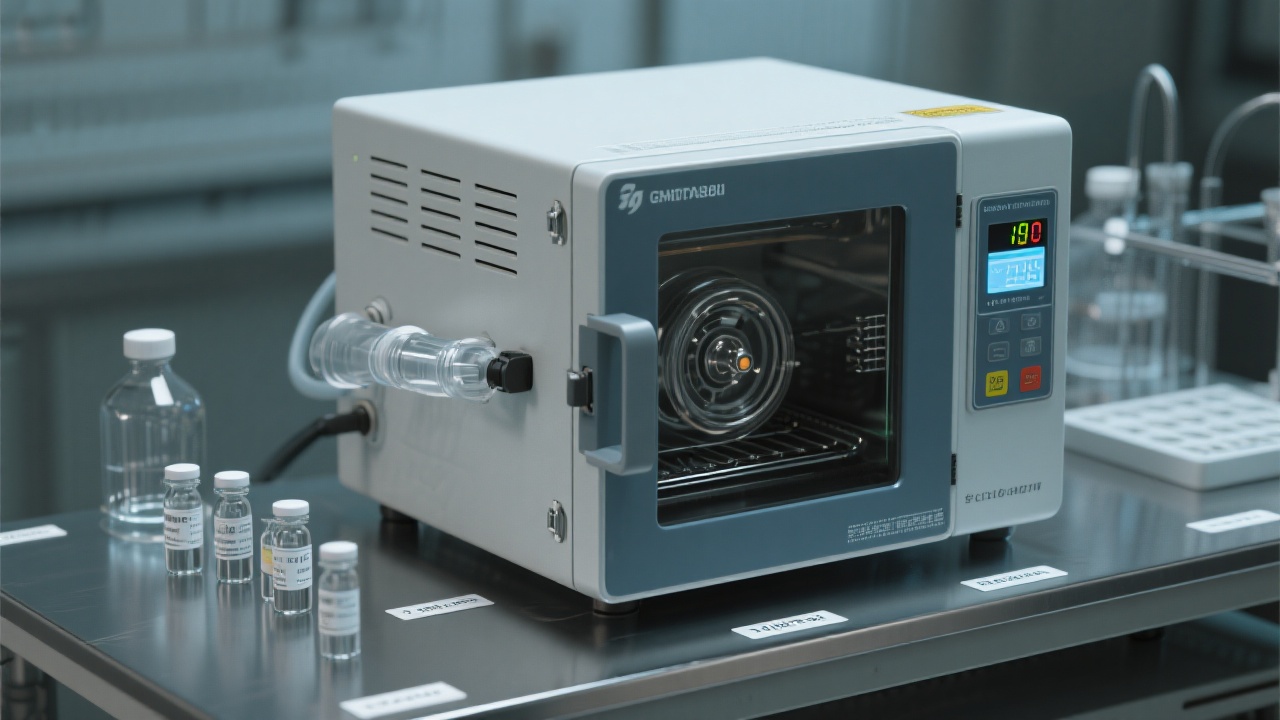

Frequent drying challenges in the chemical industry demand reliable and safe solutions. This article delves into how explosion-proof vacuum drying equipment, exemplified by the DZF-6210 large vacuum oven, ensures safe and efficient operation when handling flammable materials. Highlighting features such as precise PID temperature control within ±1℃, a corrosion-resistant 304 stainless steel chamber, a spacious 215L capacity, and certified explosion-proof design, it presents real-world applications that demonstrate improved drying efficiency and reduced incident rates. Furthermore, it emphasizes the equipment’s strong compliance with GMP and ISO standards, making it an ideal choice for chemical enterprises seeking to enhance operational safety and drying performance.

Overcoming Drying Challenges in the Chemical Industry: Why Choose Explosion-Proof Vacuum Drying Equipment?

The chemical industry frequently grapples with drying challenges that pose significant safety and efficiency risks. Residual flammable solvents and precise temperature control are critical hurdles that traditional drying methods struggle to address effectively. This article examines how explosion-proof vacuum drying equipment, particularly the DZF-6210 large-capacity vacuum oven, revolutionizes drying operations by combining advanced safety features with high performance.

The Chemical Industry’s Drying Dilemma: Safety vs. Efficiency

In chemical processing, drying volatile and combustible materials safely is paramount. Residual solvents such as benzene, acetone, or ethanol can easily ignite under uncontrolled heat. Traditional hot air or conductive drying methods often fail to maintain the narrow temperature windows required, leading to temperature overshoot, product degradation, or, in worst cases, fire hazards. Moreover, batch size limitations and slow drying rates contribute to operational bottlenecks.

| Drying Method |

Temperature Control Accuracy |

Safety Against Explosions |

Batch Capacity |

| Traditional Hot Air Drying |

±5 °C |

Low - No Explosion-Proof Measures |

Up to 100L |

| Standard Vacuum Drying |

±2 °C |

Medium - Limited Explosion Safety |

Up to 150L |

| DZF-6210 Explosion-Proof Vacuum Oven |

±1 °C (PID Control) |

High - Certified Explosion-Proof Configuration |

215L |

Technical Advantages of the DZF-6210 Explosion-Proof Vacuum Oven

The DZF-6210 sets a new industry benchmark by integrating multiple state-of-the-art features tailored for hazardous chemical drying:

- Precision PID Temperature Control with ±1 °C accuracy ensures optimal drying without overheating or product damage.

- Spacious 215L Stainless Steel (304#) Inner Chamber capable of large batch processing, reducing downtime and improving throughput.

- Durable corrosion-resistant 304-grade stainless steel interior, suitable for aggressive chemical environments.

- Explosion-proof design certified to ATEX and IECEx standards, featuring flame-proof motors, sparkproof components, and intrinsically safe electrical systems.

- Intelligent safety interlocks and alarm systems that autonomously shut down operations upon fault detection, guaranteeing operator protection.

By tightly controlling vacuum levels and heating profiles, the equipment accelerates solvent evaporation while minimizing thermal stresses. This not only secures the dryness quality but dramatically lowers risk.

Real-World Performance: Case Studies from Chemical Enterprises

Leading global chemical manufacturers adopting the DZF-6210 report remarkable improvements:

- 30%-40% reduction in drying cycle time compared to standard vacuum ovens due to enhanced vacuum and temperature precision.

- Zero incidents of explosion or fire in operations handling flammable solvents like ethanol and methanol over 18 months.

- Compliance with stringent GMP and ISO 9001 production protocols supported by repeatable, documented drying parameters.

- Higher batch volume capability reducing labor and energy costs up to 25% annually.

One case involved a specialty polymers manufacturer previously hesitant about scaling up its drying process for flammable resin precursors. Post-installation of the DZF-6210, their throughput doubled without any safety incidents, earning praise from both internal EHS auditors and external regulatory bodies.

Supporting Compliance and Sustainable Production Goals

Apart from operational benefits, the DZF-6210 directly supports compliance with international standards:

- Full alignment with GMP (Good Manufacturing Practices) ensures product consistency and safety in pharmaceutical-chemical co-processing.

- Meeting ISO 9001 and ISO 14001 standards reinforces quality management and environmental responsibility.

- Energy-efficient design reduces carbon footprint, dovetailing with corporate sustainability targets.

Its automated data-logging capabilities allow seamless integration with plant control systems, providing audit trails and facilitating continuous improvement initiatives.

Trust DZF-6210 to Make Every Drying Cycle Safe, Precise, and Efficient — Not Just Equipment, But Your Safety Shield in Chemical Processing.

Discover How the DZF-6210 Can Revolutionize Your Drying Process Today