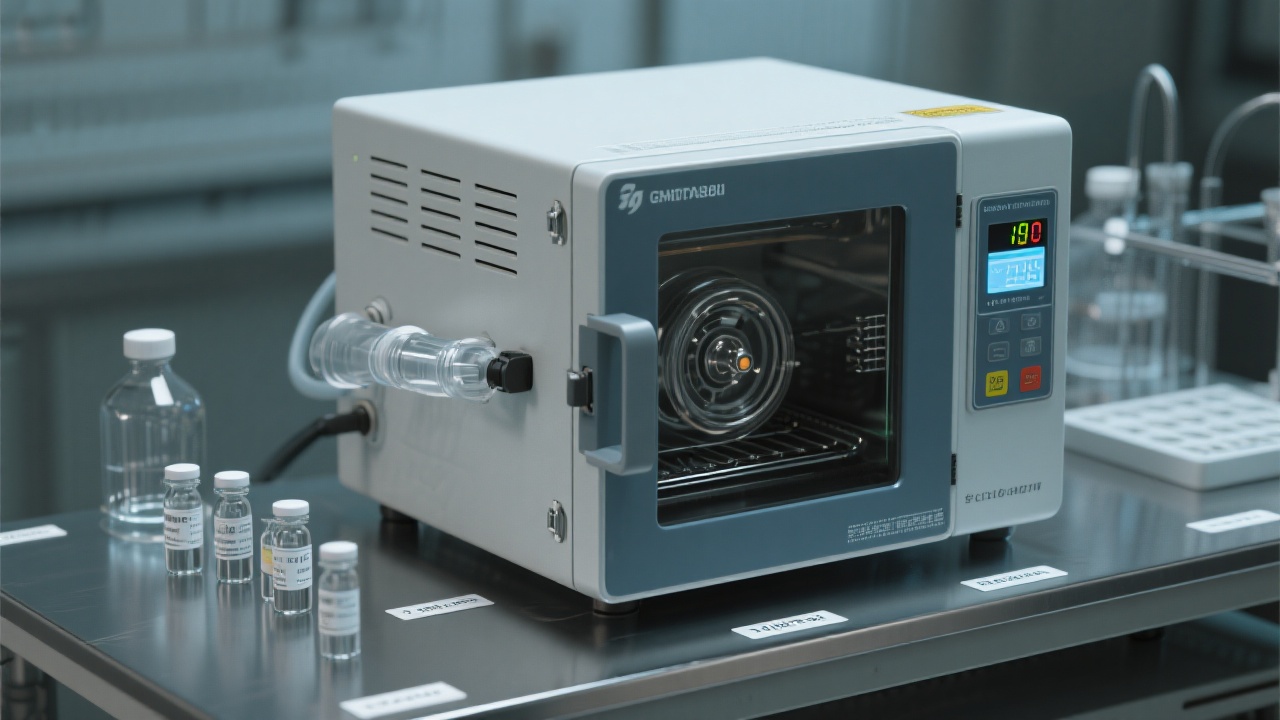

In chemical manufacturing, efficient and safe drying is more than a step—it’s a critical control point for product quality, compliance, and operational safety. Traditional batch dryers often fall short under high-risk conditions involving flammable solvents or sensitive catalysts. That’s where the DZF-6210 Explosion-Proof Vacuum Dryer steps in—not just as equipment, but as a proven solution tailored to real-world challenges.

At a mid-sized pharmaceutical plant in Germany, operators were struggling with inconsistent drying results and frequent shutdowns due to overheating during solvent recovery from reaction residues. After switching to the DZF-6210, they reported:

“We reduced drying time by 37% while eliminating thermal runaways. The vacuum control system ensured uniform heat distribution across all trays—no more hot spots.”

This isn’t an isolated case. Across Asia-Pacific labs and EU production lines, users consistently report up to 40% faster processing times when using PID-controlled vacuum drying compared to conventional ovens—especially crucial for temperature-sensitive materials like lithium-ion battery cathode powders.

| Feature | Standard Oven | DZF-6210 |

|---|---|---|

| Temperature Control | ±5°C deviation | ±0.5°C (PID algorithm) |

| Material Compatibility | Carbon steel | 304 Stainless Steel (corrosion-resistant) |

| Safety Certification | None | ATEX/IECEx certified for Zone 21 |

The key differentiator? A robust multi-layer protection system: overheat sensors, pressure relief valves, and automatic emergency venting—features that make this dryer not just reliable, but compliant with global standards such as EN 14470-1 and ISO 14624.

For R&D teams working with volatile organics or engineers managing large-scale catalyst regeneration, the ability to maintain precise vacuum levels (down to 0.1 mbar) ensures consistent moisture removal without degradation—a feature many standard dryers simply can’t deliver.

Whether you're optimizing lab-scale experiments or scaling up to industrial batches, the DZF-6210 delivers what matters most: predictable outcomes, reduced risk, and measurable efficiency gains.

Ready to transform your drying process? Let our technical team analyze your specific application and recommend a customized configuration for your facility.

Get Your Free Technical Assessment Today