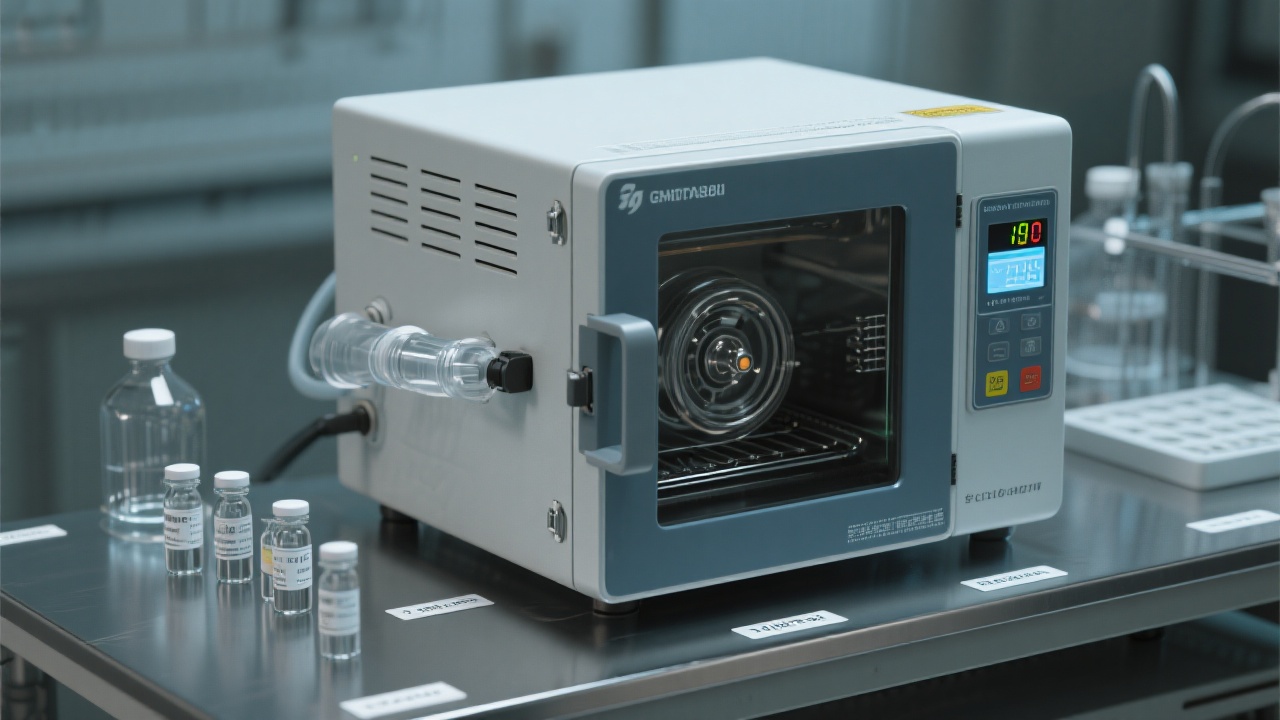

The DZF - 6210 large - scale vacuum oven is a versatile and high - performance drying solution suitable for multiple industries. With the increasing demand for high - quality drying processes in various sectors such as research institutions, pharmaceuticals, electronics manufacturing, food processing, and the chemical industry, this vacuum oven stands out as an ideal choice.

One of the key features of the DZF - 6210 is its precise temperature control. It can maintain the temperature within an accuracy of ±0.1°C. This high - level precision is crucial for industries like electronics manufacturing, where even a slight temperature deviation can lead to product defects. For example, in the production of printed circuit boards (PCBs), the precise temperature control ensures that the solder joints are of high quality, reducing the failure rate of the final products.

The DZF - 6210 comes with a large capacity of up to 210 liters. This is beneficial for industries with high - volume production requirements, such as food processing and chemical manufacturing. A food processing company can dry a large batch of fruits or grains at once, increasing the production efficiency. In the chemical industry, it can handle large - scale drying of chemical raw materials, saving time and labor costs.

Safety is a top priority, especially in industries dealing with flammable or explosive materials. The DZF - 6210 is equipped with a reliable explosion - proof function. It has passed strict safety tests and meets international safety standards. In the chemical industry, where there are often volatile chemicals, this explosion - proof design provides a secure drying environment, protecting both the operators and the products.

In the pharmaceutical industry, the DZF - 6210 can be used for drying pharmaceutical intermediates and finished products. The precise temperature control ensures that the active ingredients in the drugs are not damaged during the drying process. For example, a pharmaceutical research institution used the DZF - 6210 to dry a new type of antibiotic. The high - quality drying process helped to maintain the drug's efficacy and stability.

As mentioned before, electronics manufacturing requires high - precision drying. The DZF - 6210's precise temperature control and large capacity make it suitable for drying electronic components such as capacitors and resistors. A well - known electronics company reported that after using the DZF - 6210, the defect rate of their electronic products decreased by 15% due to the improved drying quality.

In food processing, the DZF - 6210 can be used to dry various food products. Its large capacity allows for batch processing, and the precise temperature control helps to preserve the nutritional value and flavor of the food. For instance, a fruit juice concentrate manufacturer used the DZF - 6210 to dry the concentrated juice into powder form. The resulting powder had a longer shelf - life and better rehydration properties.

The chemical industry often deals with complex drying processes. The DZF - 6210's explosion - proof design and large capacity are highly valuable. A chemical plant used the DZF - 6210 to dry a flammable chemical compound. The explosion - proof function ensured the safety of the drying process, and the large capacity increased the production output.

The DZF - 6210 features a human - friendly operation design. The control panel is easy to use, and operators can quickly set the required temperature and drying time. The intelligent temperature control system can automatically adjust the temperature according to the set parameters, improving the drying efficiency and safety. It also has a real - time monitoring function, allowing operators to keep track of the drying process at any time.

To ensure the long - term stable operation of the DZF - 6210, regular maintenance is necessary. It is recommended to clean the interior of the oven every three months and check the sealing performance of the door. If there are any abnormal noises or temperature fluctuations during operation, please contact our professional after - sales service team. We also provide a detailed FAQ section on our website to answer common questions, which can enhance users' confidence in using the product.

We encourage you to leave your comments and questions below. Your feedback is very important to us as it helps us to improve the content and make it more useful for you. If you are interested in learning more about the DZF - 6210 large - scale vacuum oven or need a customized drying solution, click here to contact us now!