According to the U.S. National Fire Protection Association (NFPA), over 30% of laboratory fires originate from improper handling of volatile substances—many of which could be prevented with proper equipment selection and standardized procedures. In high-risk environments such as pharmaceutical research labs or chemical synthesis facilities, even a minor spark can lead to catastrophic outcomes.

Laboratories often handle flammable solvents like acetone, ether, or ethanol at elevated temperatures. Without strict controls, these materials become hazardous when exposed to heat sources or static electricity. A study by the UK Health and Safety Executive (HSE) found that 67% of lab incidents involving explosive samples occurred during drying processes due to inadequate ventilation or outdated equipment.

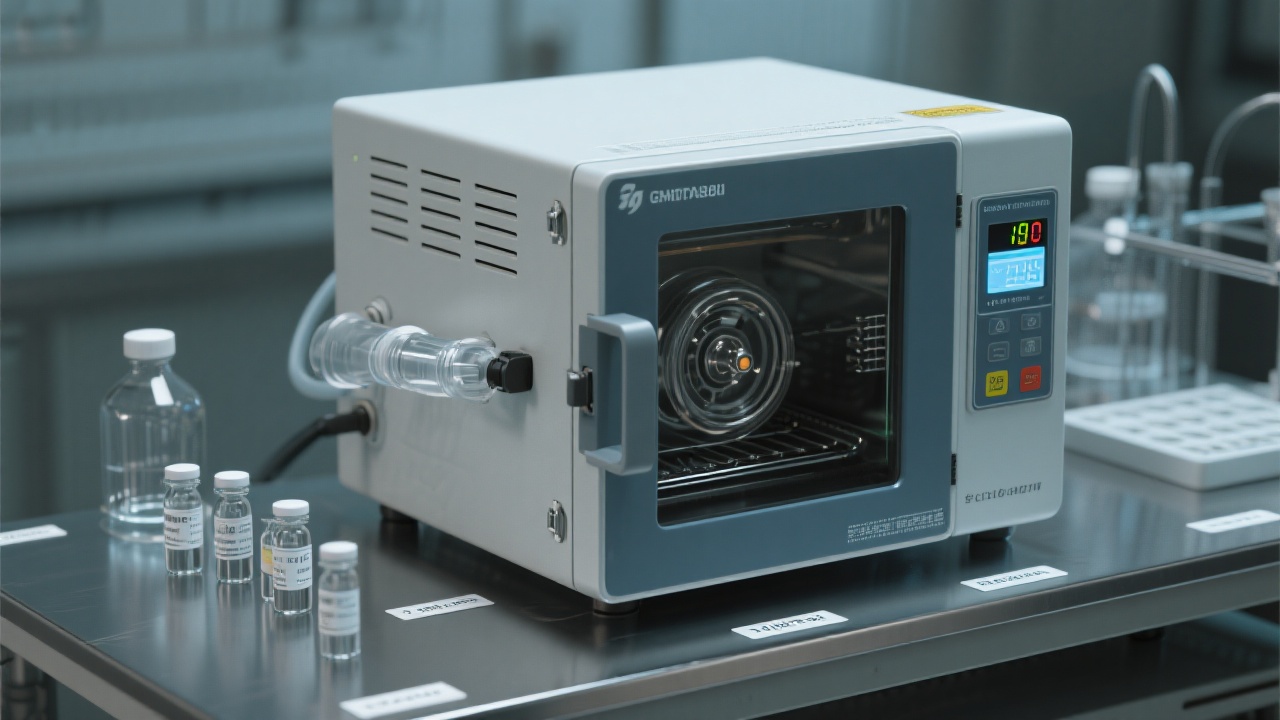

The key lies in controlling oxygen levels and temperature uniformity. For example, the Zhengzhou Keda DZF-6010 Mini Vacuum Oven features an explosion-proof design certified under IECEx and ATEX standards, ensuring safe operation even with solvents having flash points below 60°C. Its double-layered stainless steel chamber and precision temperature control (±0.5°C accuracy) reduce thermal stress on samples while minimizing fire risks.

At a leading university in Germany, researchers reported zero incidents after switching to the DZF-6010 model for solvent removal in polymer synthesis. Their QA team noted a 40% improvement in process consistency and a 60% reduction in downtime caused by safety alerts—a direct result of reliable explosion-proof engineering.

Pro Tip: Always review your lab’s Material Safety Data Sheets (MSDS) before introducing any new sample type into a vacuum oven. Many modern systems now integrate with LIMS software for automated compliance tracking—an essential upgrade for ISO-certified labs.

Whether you're managing a small academic lab or a large industrial R&D facility, investing in certified explosion-proof equipment isn’t just smart—it’s mandatory. The DZF-6010 has helped hundreds of labs worldwide meet global safety benchmarks without compromising efficiency.

Explore the DZF-6010 Vacuum Oven – Engineered for Safety First