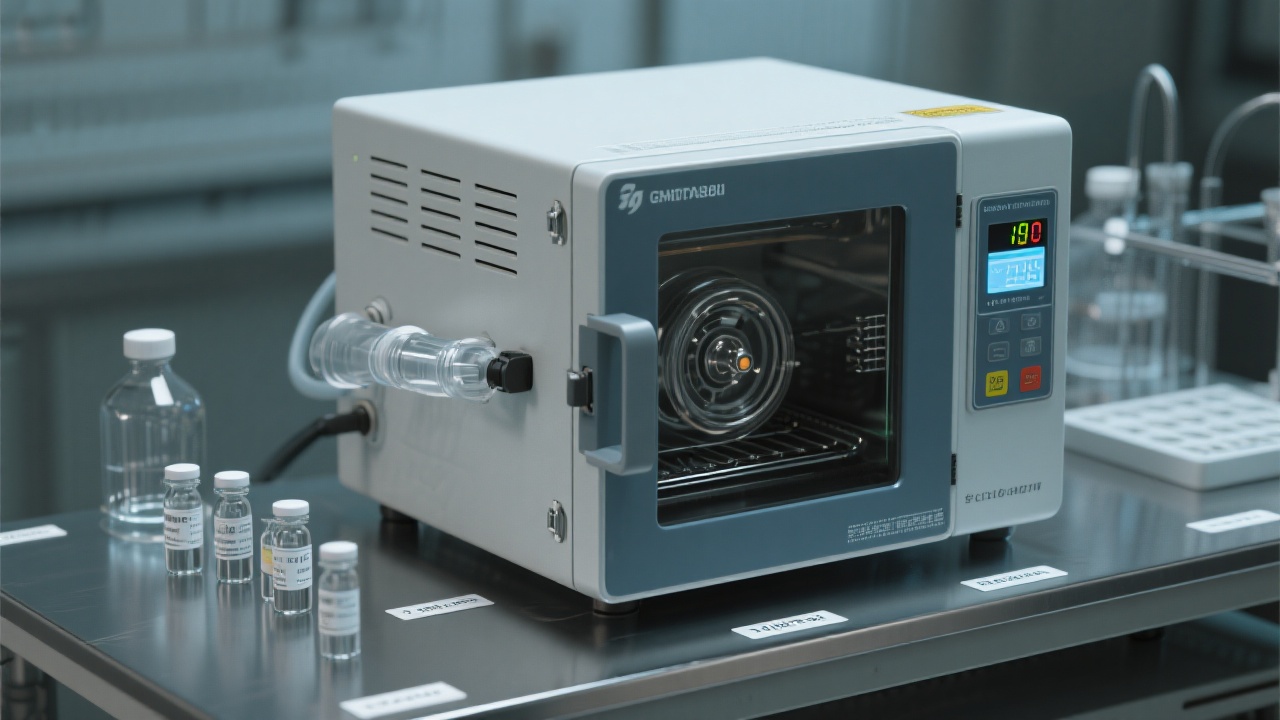

In the highly competitive electronics manufacturing industry, the consistency of material drying is crucial for product quality and production efficiency. The DZF - 6210 Large Vacuum Oven, with its advanced precise temperature control technology, offers a reliable solution to meet these demands.

The core of the DZF - 6210 lies in its precise temperature control technology. It is equipped with a PID (Proportional - Integral - Derivative) intelligent temperature control system. This system can accurately adjust the temperature within a narrow range, typically with an accuracy of ±0.1°C. This high - precision control ensures that the materials in the oven are dried under a stable temperature environment, which is essential for achieving consistent drying results.

For example, in a large - scale electronics manufacturing plant, when drying circuit boards, a slight temperature deviation can lead to uneven drying, which may cause issues such as solder joint defects or reduced component performance. With the DZF - 6210's PID intelligent temperature control, these problems can be effectively avoided, improving the overall quality of the products.

The DZF - 6210 features a large - capacity design, with an internal volume of up to 621 liters. This large capacity makes it suitable for mass production in the electronics manufacturing industry. Whether it is drying a large number of small components or a few large - sized materials, the oven can handle it efficiently.

In addition, the oven is made of high - quality and durable materials, which can withstand long - term use in harsh industrial environments. The intelligent control system not only provides precise temperature control but also offers functions such as temperature programming and real - time monitoring. Operators can easily set the drying parameters according to different material requirements, and the system will automatically adjust the temperature and time to ensure the best drying effect.

| Feature | Description |

|---|---|

| Capacity | 621 liters |

| Temperature Accuracy | ±0.1°C |

| Control System | PID Intelligent Temperature Control |

Let's take a case study of an electronics manufacturer. Before using the DZF - 6210, they faced problems such as inconsistent drying of electronic components, which led to a high defect rate of about 10%. After adopting the DZF - 6210 vacuum oven, the defect rate dropped significantly to less than 2%. This shows that the oven can effectively improve the consistency of material drying and reduce production losses.

The large - capacity design also allows the manufacturer to increase the batch size of drying, which has increased the production efficiency by about 30%. At the same time, the safety configuration and user - friendly operation of the oven have reduced the labor intensity of operators and improved the overall work efficiency.

The electronics manufacturing industry is constantly evolving, and the requirements for material drying technology are also getting higher. The latest drying technology trends include more precise temperature control, energy - saving, and environmental protection. The DZF - 6210 meets these trends with its advanced technology and design.

For example, the PID intelligent temperature control system not only ensures precise temperature control but also saves energy by reducing unnecessary temperature fluctuations. By following the latest industry standards and using scientific drying processes, manufacturers can improve the quality of their products and gain a competitive edge in the market.

In conclusion, the DZF - 6210 Large Vacuum Oven is an ideal choice for electronics manufacturing and related industries. Its precise temperature control technology, large - capacity design, and intelligent control system can help manufacturers achieve consistent material drying, improve production quality and efficiency, and reduce costs. Don't miss out on this opportunity to enhance your manufacturing process! Click here to learn more and consult with our experts.