Digital Temperature Control System in Biopharmaceutical Drying: Efficient Performance and Quality Assurance

13 01,2026

Zhengzhou Keda Mechanical Instrument Equipment Co., Ltd.

Customer Cases

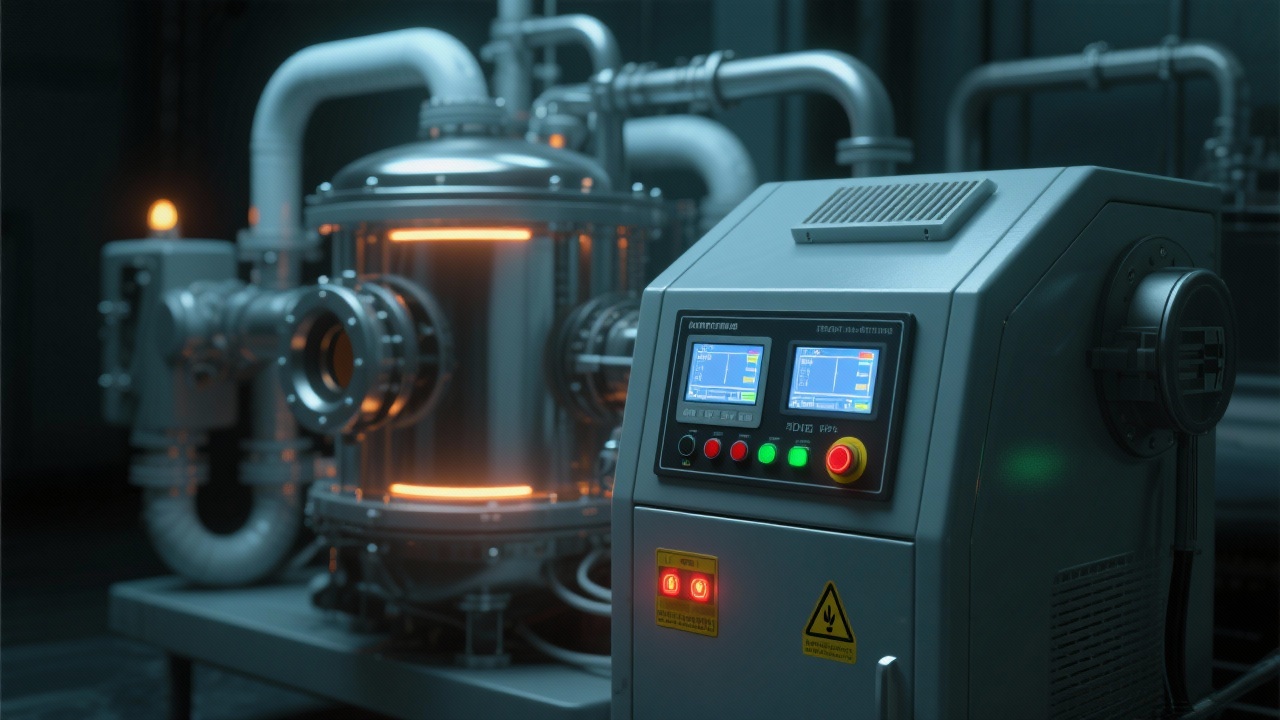

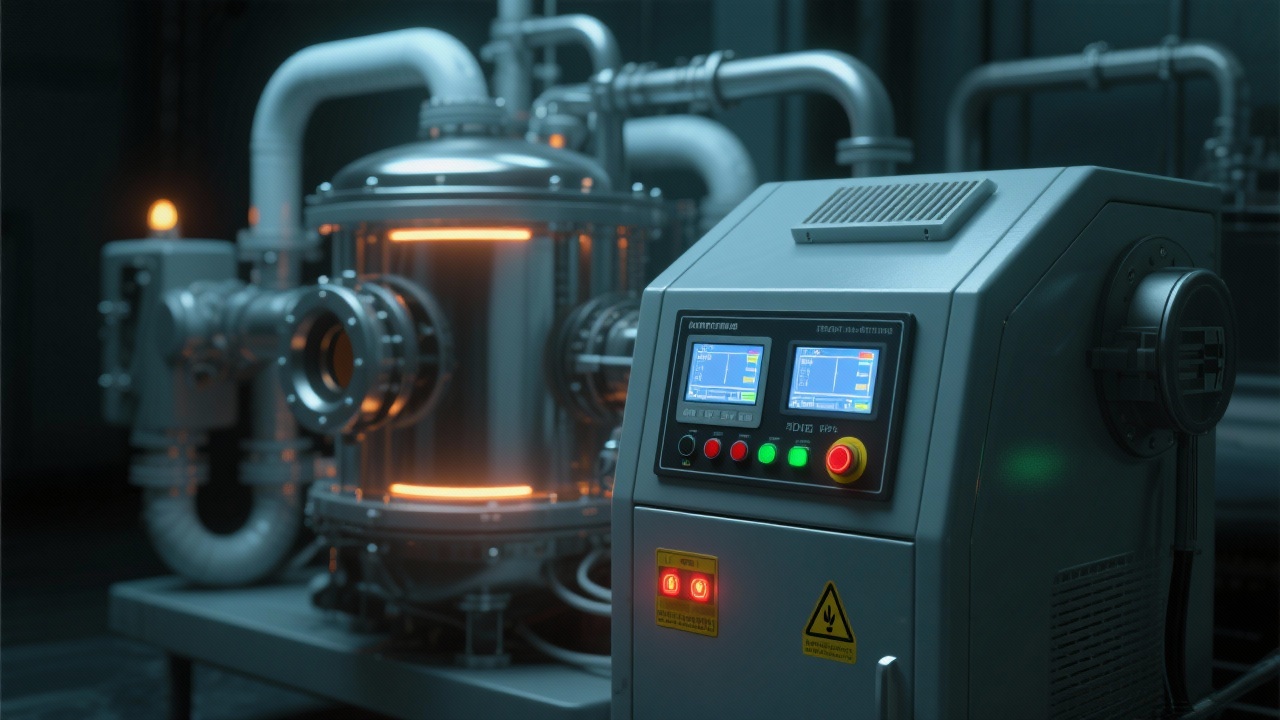

This article explores the advanced digital temperature control system of Zhengzhou Keda Machinery Instrument Equipment Co., Ltd.'s DZ-3BCII vacuum drying oven, focusing on how PID control technology ensures precise, uniform, and stable temperature regulation. Through technical analysis, parameter optimization strategies, and real-world applications in biopharmaceutical drying, it demonstrates how intelligent temperature control enhances drying efficiency and safeguards product quality. Practical case studies and troubleshooting tips provide actionable insights for researchers and industrial users. The article concludes with an outlook on future trends in digital control systems—offering a forward-looking reference for equipment modernization in pharmaceutical processing.

How Smart Temperature Control Boosts Efficiency in Biopharma Drying

In the pharmaceutical industry, drying biological samples—like antibodies or cell cultures—is both an art and a science. Even minor temperature fluctuations can compromise product integrity, reduce yield, or trigger regulatory non-compliance. That’s why leading labs and manufacturers are turning to digital control systems like those found in the DZ-3BCII Digital Vacuum Dryer from Zhengzhou Keda Machinery Instrument Equipment Co., Ltd.

Precision Through PID: The Core of Reliable Drying

The heart of this system is its advanced PID (Proportional-Integral-Derivative) algorithm—a proven method used in over 85% of industrial temperature controllers worldwide (source: IEEE Industrial Electronics Society). Unlike basic on/off thermostats, PID continuously adjusts heating power based on real-time feedback, maintaining a setpoint within ±0.5°C across a 50–120°C range. In practice, this means:

- Reduced drying time by up to 20% compared to conventional ovens

- Elimination of hotspots that cause uneven dehydration

- Consistent results across multiple batches—critical for GMP compliance

Real-World Impact: A Case Study from BioPharma R&D

At a mid-sized biotech lab in Germany, researchers were struggling with inconsistent lyophilization outcomes using older equipment. After switching to the DZ-3BCII with its smart PID-controlled vacuum chamber, they saw:

| Metric |

Before Upgrade |

After DZ-3BCII |

| Temp Uniformity (°C) |

±3.2 |

±0.4 |

| Cycle Time (hrs) |

18 |

14.5 |

| Batch Success Rate |

78% |

96% |

Optimization Tips for Maximum Performance

While the DZ-3BCII comes pre-calibrated, optimizing PID parameters for your specific material (e.g., proteins vs. vaccines) can further improve efficiency. For instance:

- Start with default values (Kp=2.5, Ki=0.1, Kd=0.05), then fine-tune based on response curves

- Use step-change tests to observe overshoot and settling time

- Log data via built-in USB port for continuous improvement

Ready to Transform Your Drying Process?

See how the DZ-3BCII digital vacuum dryer delivers precision, consistency, and speed—backed by real-world data from global clients.

Explore the DZ-3BCII Smart System Now