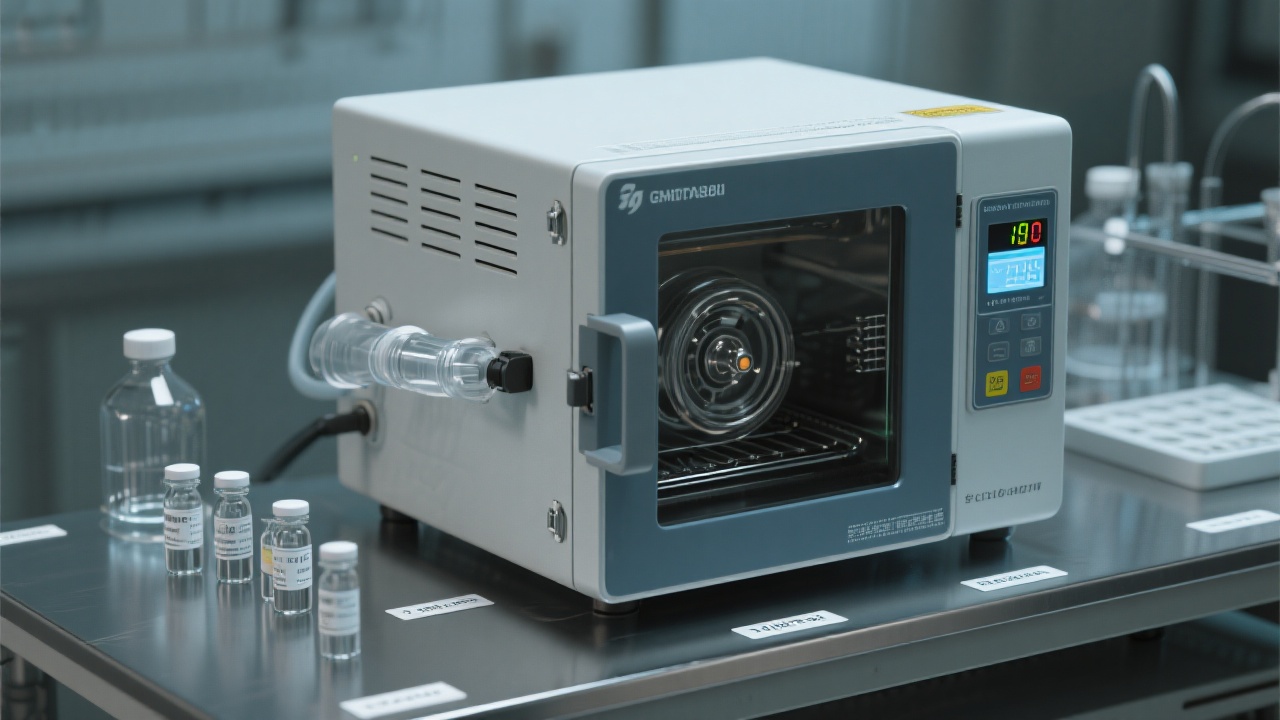

In the realm of laboratory and industrial drying processes, the DZF-6210 Large Vacuum Oven stands out as a remarkable solution. This high - efficiency vacuum drying equipment is meticulously designed to meet the diverse needs of both laboratory research and large - scale industrial production.

The DZF - 6210 features a generous 215L capacity, which is ideal for handling large - volume samples or products. This large capacity significantly reduces the need for multiple drying cycles, thereby enhancing overall productivity. The interior of the oven is lined with 304 stainless steel. This material is not only resistant to corrosion but also easy to clean, ensuring a long - lasting and hygienic drying environment. According to industry standards, 304 stainless steel is a top - choice material for equipment in contact with various substances, especially in the pharmaceutical and food industries.

One of the key selling points of the DZF - 6210 is its precise temperature control. It can maintain a temperature range from room temperature to 250°C, with an accuracy of ±1°C. This high - precision temperature control is achieved through the advanced PID intelligent temperature control system. Compared with traditional temperature control methods, PID control can quickly adjust to the set temperature and maintain a stable temperature throughout the drying process. In the pharmaceutical industry, for example, precise temperature control is crucial for ensuring the stability and efficacy of drugs. A slight deviation in temperature can lead to changes in the chemical properties of the drugs, affecting their quality and safety.

Safety is always a top priority in both laboratory and industrial settings. The DZF - 6210 offers an optional safety explosion - proof design. This feature is particularly important in industries such as electronics manufacturing, where the presence of flammable solvents or gases is common. The explosion - proof design meets the strictest industry safety standards, providing users with peace of mind. Additionally, the oven is equipped with multiple safety protection mechanisms, such as over - temperature protection and over - current protection, further ensuring the safety of the equipment and operators.

The DZF - 6210 has found wide applications in multiple industries. In the pharmaceutical industry, it can be used for drying raw materials, intermediates, and finished products. By providing a stable and precise drying environment, it helps to improve the purity and stability of drugs. In the electronics manufacturing industry, the oven is used to dry electronic components, such as printed circuit boards and semiconductor chips. The high - precision temperature control and large capacity can effectively remove moisture from these components, improving their performance and reliability. In the chemical industry, it can be used for drying various chemical products, such as polymers and catalysts, enhancing their quality and reactivity.

Let's take a look at some real - world case studies. A pharmaceutical company was struggling with inconsistent drying results using their old equipment. After switching to the DZF - 6210, they noticed a significant improvement in the quality of their drugs. The precise temperature control ensured that the active ingredients in the drugs remained stable, and the large capacity reduced the drying time by 30%. In an electronics manufacturing plant, the use of the DZF - 6210 led to a 20% reduction in the defect rate of electronic components due to better moisture removal.

In conclusion, the DZF - 6210 Large Vacuum Oven is a high - performance, reliable, and versatile vacuum drying solution. Its hardware advantages, precise temperature control, and safety features make it an ideal choice for a wide range of industries. Whether you are a professional purchaser looking for a high - quality drying equipment or a technical expert seeking to optimize the drying process, the DZF - 6210 is definitely worth considering. Are you interested in learning more about how the DZF - 6210 can benefit your business? Click here to get in touch with our experts and explore this amazing product further!

We encourage you to leave your comments and questions below. Share your thoughts on how the DZF - 6210 could fit into your industry or ask us anything you want to know about the product!